News

-

How to efficiently machine complex curved surfaces in automobile mold parts?

In modern automobile manufacturing, the aesthetic design of body panels increasingly emphasizes fluidity and dynamism, leading to increasingly complex geometries in automobile mold parts, employing numerous free-form surfaces, deep cavity structures, and

Learn More2025-10-29 -

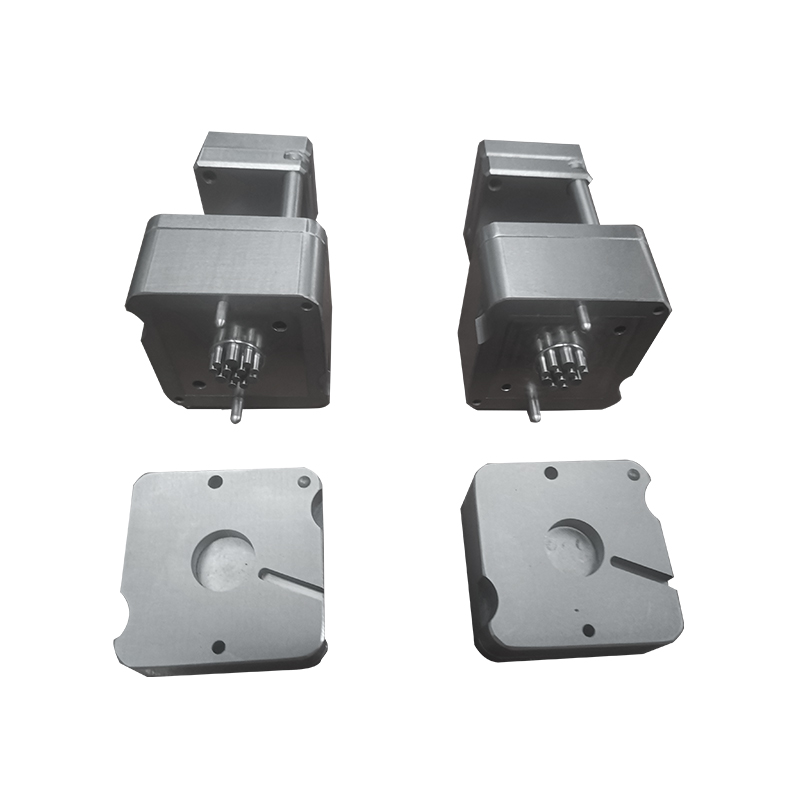

How to balance machining efficiency and surface roughness when machining a power plug mold with CNC?

The surface of the mold after CNC processing may have micro cracks or residual stress, and the surface quality needs to be further improved through polishing, sandblasting or nitriding.

Learn More2025-10-17 -

How do automobile mold parts define the precision ceiling of vehicle manufacturing?

It can be said that the machining accuracy and stability of automobile mold parts directly determine the precision ceiling of vehicle manufacturing and are the source of quality assurance.

Learn More2025-10-02 -

How can we ensure that the power plug mold does not deform under high pressure?

Ensuring the structural stability of the power plug mold under high pressure is crucial for ensuring product quality and production efficiency.

Learn More2025-09-18 -

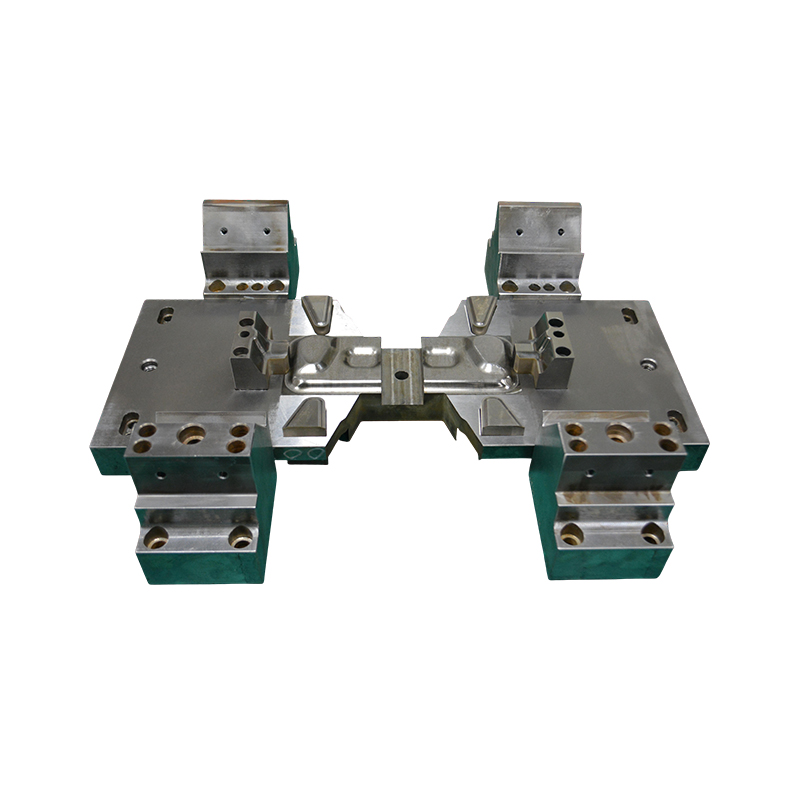

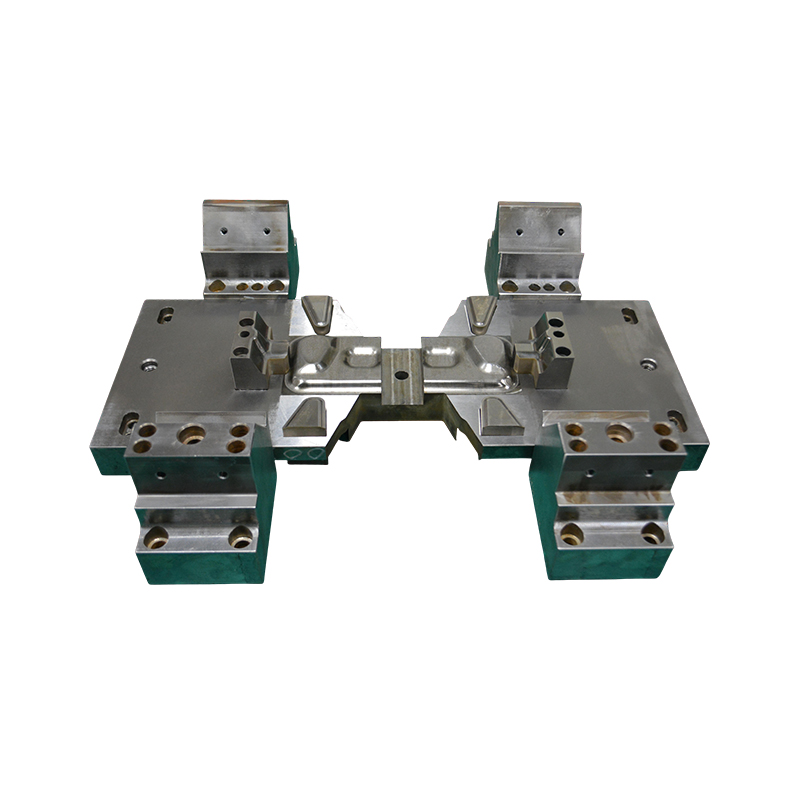

How do automobile mold parts sliders maintain stability while molding complex curved surfaces under high-temperature, high-pressure injection molding environments?

In modern automobile manufacturing, injection molding is widely used for interior and exterior trim, functional components, and other automotive mold parts sliders.

Learn More2025-09-04 -

How can power plug molds shorten production cycles?

As a core tool in the injection molding process, the design and performance of the power plug mold largely determine the length of the production cycle.

Learn More2025-08-21