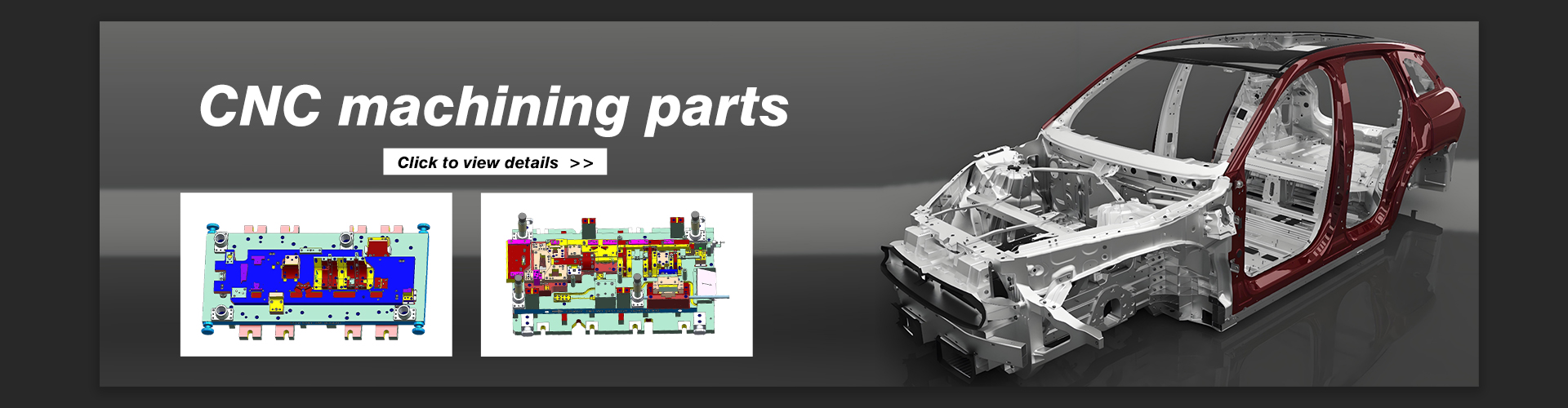

Automobile Mold Parts Slider

It can handle complex curved surfaces, deep cavities, thin walls and porous structures, and meet the precision design of slider parting surfaces, guide rail grooves, etc. It supports customers to provide 2D/3D drawings for customization.