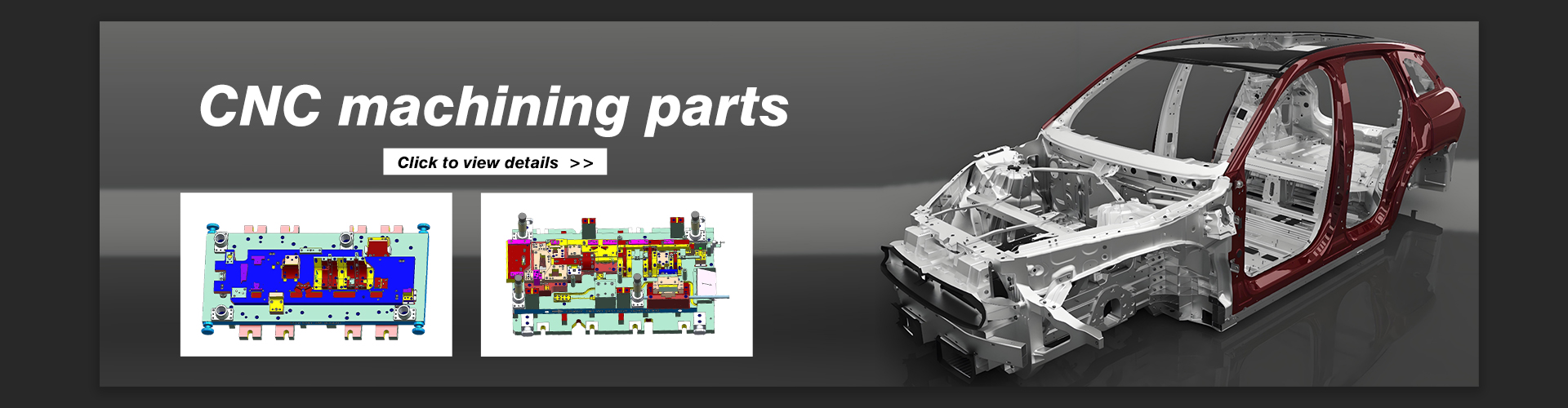

Automobile Mold Parts

It can process complex curved surfaces, deep cavities, thin-walled structures and multi-hole parts (such as inclined top sliders, special-shaped inserts), and supports micro-feature processing (minimum hole diameter Φ0.5mm). Advanced equipment: equipped with five-axis linkage CNC machining center, high-speed milling center, slow wire cutting and vacuum quenching furnace, covering the entire process from rough machining to super finishing.